Multiple Sourcing – GetAhead Asia

In today’s fast-paced and interconnected business world, adaptability is not just an advantage, but a fundamental requirement. With this in mind, GetAhead Asia aims to help companies achieve this crucial flexibility through the use of multiple sourcing strategies. This innovative approach aims to increase the robustness and efficiency of your supply chains by not only increasing security of supply, but also optimizing cost structures and improving product quality. By activating and carefully managing a broad network of suppliers, we enable your company to adapt quickly to market changes and stay one step ahead.

What is multiple sourcing?

The concept of multiple sourcing, i.e. the procurement of goods and services from different sources, is an advanced strategy that allows companies to significantly reduce their dependence on individual suppliers. This versatile procurement method helps to strengthen a company’s market position by creating greater flexibility and reliability in the supply chain. It also plays a crucial role in mitigating the risks associated with supply shortages and disruptions. By using a wider range of sources of supply, companies can not only improve their negotiating position, but also optimize the quality of the goods they buy and potentially save costs at the same time.

A key advantage of multiple sourcing is the promotion of healthy competition among suppliers, which often leads to better prices, higher quality and more innovative solutions. As a result, companies benefit from an improved negotiating position, which enables them to negotiate more favorable conditions. In addition, the strategy of multiple sourcing enables greater adaptability to market changes, as companies have the opportunity to flexibly divide their orders between different suppliers.

Why multiple sourcing with GetAhead Asia?

GetAhead Asia combines local market knowledge and advanced technology to identify suppliers in Asia that are precisely tailored to your sourcing needs. Our AI-powered tools facilitate effective supplier selection, while our comprehensive risk management and stringent quality controls ensure the reliability and compliance of your supply chain. This diversification strategy minimizes risks such as shortages and strengthens the resilience of your business operations. At the same time, competition among suppliers enables better prices and conditions, which optimizes your cost structure and increases your company’s competitiveness. With our expertise in strategic planning and operational experience, we support you in responding proactively not only to current but also to future challenges.

In practice, multiple sourcing can be applied in various forms, from sourcing identical parts from different manufacturers to using specialized suppliers for different components of a product. The key to success lies in careful planning and building strong, transparent relationships with suppliers.

Our services in the area of multiple sourcing

GetAhead Asia specializes in using its in-depth local market knowledge in Asia and advanced technologies to precisely identify the optimal suppliers for its clients’ specific requirements. This process includes a thorough quality and compliance review to ensure that each supplier meets high standards. Through strategic negotiations and careful contract drafting, GetAhead Asia uses its insider knowledge to obtain the best terms for its customers. Continuous risk management and monitoring of supplier relationships are other key elements of their approach, helping to safeguard customers’ supply chains against unforeseen events while ensuring efficiency and reliability. This comprehensive support is made possible by a combination of technology-based solutions and an in-depth understanding of regional characteristics.

Start your multiple sourcing journey with GetAhead Asia

Let’s work together to build a robust, efficient and cost-effective supply chain. Contact us today for a no-obligation initial consultation and find out how we can support your business.

Recent ASEAN sourcing trends include a shift towards digitalization and sustainability. Companies are increasingly using digital platforms for supplier discovery, procurement, and supply chain management. There is also a growing emphasis on ethical sourcing, environmental sustainability, and reducing carbon footprints in the supply chain.

Read about trends and news here: https://getahead-asia.com/knowledge/

The role of Vietnam in the global procurement market landscape is changing. In the past, the country has been known for agricultural products and its textile and shoe production. Meanwhile, Vietnam has moved up the value chain. Not only electronic component assembly can now be found here, but also an increasing number of components and materials producers have located their production in Vietnam.

Additional information regarding sourcing from Vietnam can be found in our country market profile: https://getahead-asia.com/vietnam/

India offers a larger variety of high-quality products than most procurement experts would expect. Frequent sources of knowledge that we observe are company owners who have relocated back to India or through Joint Ventures and Spin-Offs. Examples of parts that we have helped procuring include automotive components, metals parts, electronics, sensors, and cooling technology. More upfront screenings and local visits might be required – GetAhead Supply Chain Solutions is perfectly positioned to help you with this.

Additional information regarding sourcing from Vietnam can be found in our country market profile: https://getahead-asia.com/india/

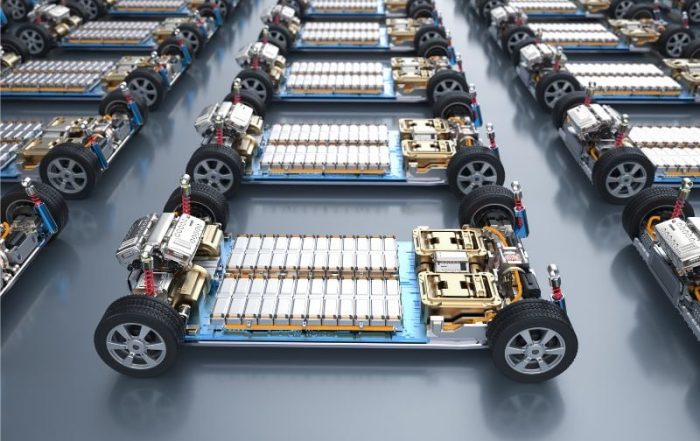

Southeast Asia and India are emerging manufacturing hubs for a wide range of goods, offering lower production costs compared to East Asia. Examples include electronics, appliances, the vehicle industry, and automotive powertrain components. Additionally, they serve traditionally labor-intensive industries such as textiles and complex assemblies.

For electronics, chips and labor-intensive assembly, sourcing in Asia is still important an important task for most manufacturing businesses. Contract manufacturers in Asia have grown over decades and pool production volumes for their clients which enables them to offer crucial cost savings.

Diversify your supply chains now!

Strategic Shift in Asian Procurement: Finding New Opportunities and Strengthening Supply Chains

Join us on November 14, 2024, at the 59th BME Symposium for Procurement & Logistics in Berlin’s STATION venue, where we’ll explore the future of international trade and sourcing. The focus of this event, [...]

GetAhead Supply Chain Solutions Presents on De-Risking Supply Chains in Asia at Handelsblatt Chief Procurement Officer Summit

Düsseldorf, April 11, 2024 - Mathias Alt, Managing Partner & Founder of GetAhead, contributed to the Handelsblatt Chief Procurement Officer (CPO) Summit with a speech on the topic 'The CPO as a Navigator in [...]

Next-Generation Batteries: Energy Transition Powered by Japan

Japan is leading the charge in the technological revolution, particularly in pioneering the development of next-generation battery technology, such as solid-state batteries. This innovation is transforming the electric vehicle (EV) sector, renewable energy storage [...]