Japan’s Pioneering Role in Organic Electronics and Beyond

Japan’s electronics manufacturing landscape continues to evolve at a rapid pace, driven by advances in organic electronics, artificial intelligence (AI), the Internet of Things (IoT), and 3D-printed electronics. These trends are not only reshaping Japan’s industry but also exerting a profound influence on the global electronics market.

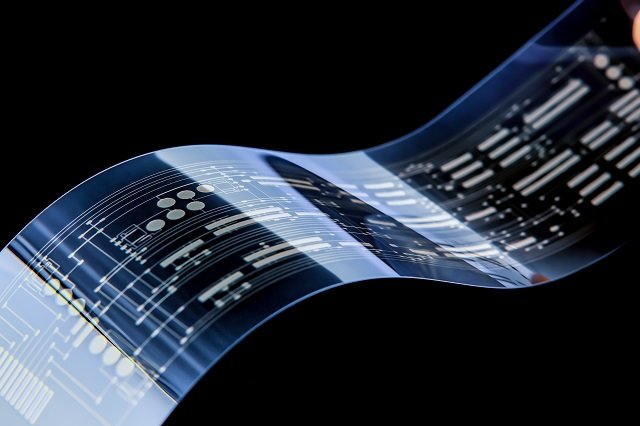

Printed Organic Electronics. Credit: https://www.jetro.go.jp/

Organic Electronics: A Sustainable Future

The rise of organic electronics, particularly organic light-emitting diode (OLED) technologies, marks a significant shift in Japan’s electronics manufacturing. Companies like Sony and Panasonic are incorporating OLEDs into a wide range of devices, from smartphones and TVs to wearable devices. These organic electronics offer remarkable benefits in terms of energy efficiency and flexibility, paving the way for more sustainable electronic products. The shift towards OLED technology reflects Japan’s commitment to reducing environmental impact and advancing towards greener manufacturing practices.

Core Components and Manufacturing of Organic Electronics

The components involved in organic electronics are primarily organic molecules or polymers that possess the ability to conduct electricity. These materials are used to create various elements essential for electronic devices, such as the organic semiconductors in OLEDs, which emit light when an electric current passes through them. Another component, organic photovoltaic cells, convert sunlight into electricity using organic materials. Additionally, there are organic light-emitting transistors, which combine the light-emitting properties of OLEDs with the switching capabilities of transistors, opening new possibilities for integrated circuits.

The manufacturing process of organic electronics differs significantly from that of traditional inorganic electronics. It often involves printing techniques, such as inkjet or screen printing, which allow for the production of electronic devices on flexible substrates, such as plastic or paper. This process is typically less energy-intensive and requires lower temperatures than the production of silicon-based electronics, leading to reduced environmental impact and lower manufacturing costs.

Japanese Innovation in Organic Electronics: Applications and Environmental Impact

Japanese companies are utilizing these benefits to create a wide range of products, from flexible displays and lightweight solar panels to advanced sensors and lighting solutions. For instance, Sharp is developing advanced OLED displays for smartphones and televisions, while Fujifilm is focusing on the potential of organic materials in healthcare applications, such as in organic biosensors. Sumitomo Chemical, on the other hand, is expanding the possibilities of organic materials in lighting and energy generation, reflecting the broad potential of organic electronics.

The shift towards organic electronics aims to address several problems inherent in the electronics industry. For one, the reliance on scarce or harmful materials like rare earth elements and heavy metals is reduced, alleviating environmental and supply chain concerns. Additionally, the energy efficiency of organic devices plays a crucial role in combating electronic waste and reducing the carbon footprint of electronic products.

Emerging Trends in Japanese Electronics: From 3D Printing to AI and Miniaturization

Other trends include revolution of 3D-printed electronics, shown by Mitsubishi Electric’s adoption of the technology to enhance the production of HVAC components and develop complex prototypes, leading to more efficient operations. Additionally, the integration of AI into manufacturing processes, demonstrated by companies like Fujitsu and NEC, is optimizing efficiency, reducing waste, and advancing product functionality. Furthermore, Japanese firms like TDK and Murata Manufacturing are advancing in miniaturization and high-density integration, producing smaller, more efficient components essential for modern consumer electronics. These advancements are not only elevating Japan’s status as a leader in electronics innovation but are also aligning with global sustainability goals by conserving materials and energy.

Implications for International Business, Manufacturing, and Procurement

These technological advancements have significant implications for international business and procurement. As Japanese electronics manufacturers adopt these cutting-edge technologies, they set new global standards for quality, efficiency, and sustainability. International businesses must adapt to these changes, aligning their procurement strategies with the evolving landscape and fostering partnerships with Japanese firms to stay competitive.

Moreover, the global supply chain is affected as companies outside Japan may need to upgrade their technologies and practices to meet the emerging standards. This could lead to increased collaboration and technology transfer between Japanese companies and their global counterparts, fostering a more interconnected and innovative global electronics industry.